Advance Oxidation Process Application Water

& Wastewater Treatment

Partnership Based On Trust

AOP

Advance Oxidation Process

"AOP uses one of the strongest known oxidant, the highly reactive hydroxyl radicals which if applied in water can virtually oxidize any compound present in the water matrix. It can reduce the concentration of contaminants with 90% at most efficiency, which earned it the credit of "water treatment process of the 21st century"

The Technology

The ELFLASH Construction Services version of AOP was designed and formulated with great consideration on operational expenses. The idea was to come up with a performance consistent system that will also be economically viable to operate even for small businesses. The concentration of Advance Oxidation Process system design is the combination of ozone gas + water with high pH, which proves to be effective and yet financially viable to operate. The 2020 system design is consistently compliant to DAO 2016-08 parameters of the DENR and have provisions reserve for 100% recycling if opted by the client.

The main goal of ELFLASH Construction Services is to developed a highly effective system design, with locally fabricated equipment for water and waste water treatment that can be affordable even to small industries. Clean and safe water resources can be attained only if everybody, no matter how big or small will be involved. This is our way of responding to our government appeal for mitigating the effect of climate change, thru implementation of economically viable ecological restoration programs.

AOP

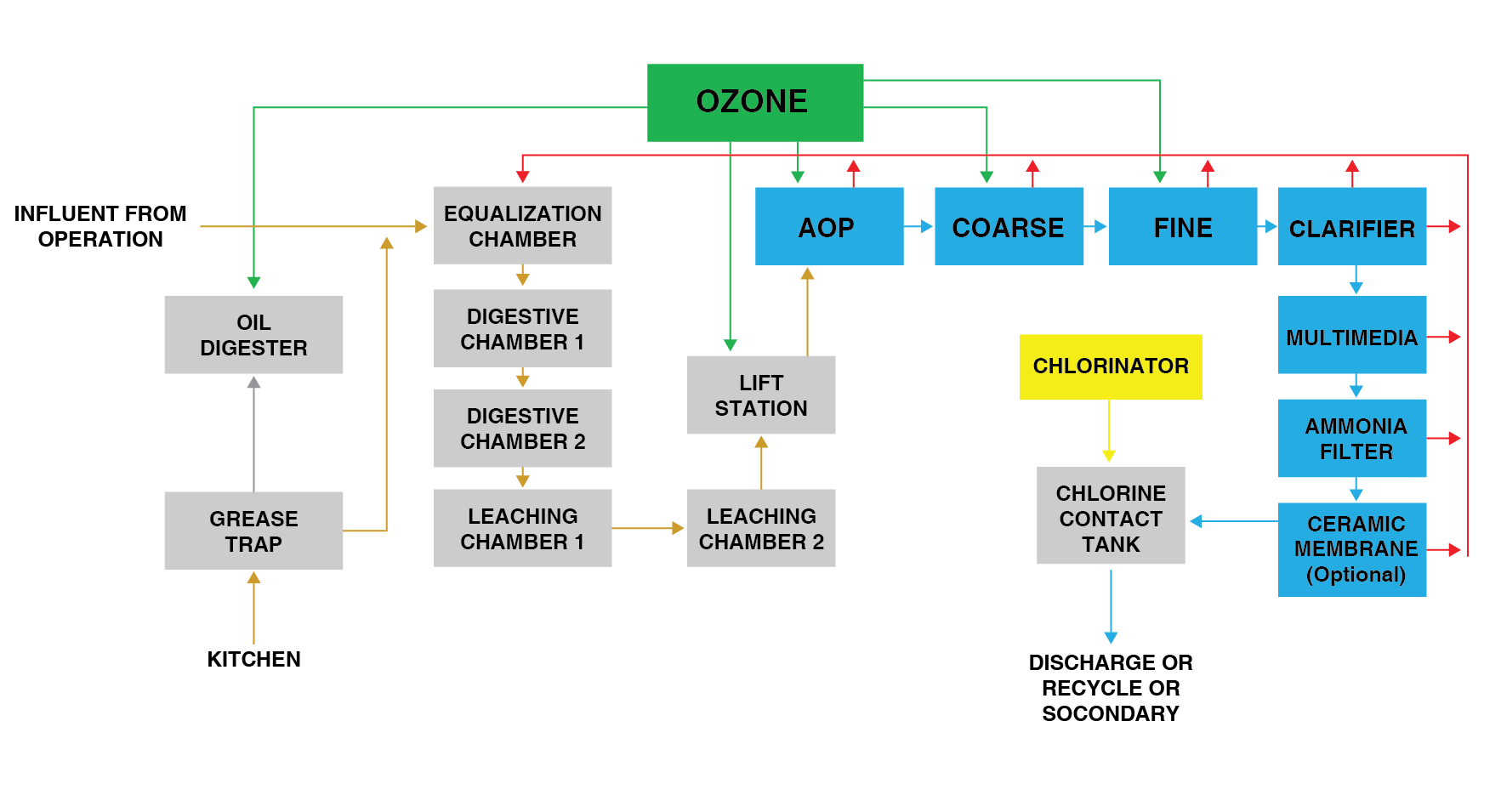

AOP SYSTEM FLOW DIAGRAM

The ELFLASH Construction Services way of applying the Advance Oxidation Process for wastewater

treatment has two basic components, the anaerobic digester and the AOP equipment.

In the anaerobic digester, the influent undergoes at least 45% removals of organic contaminants which also resulted to elevation of pH level. The AOP equipment on the other hand, saturated the influent with ozone until it reaches the point where a chemical reaction occurs resulting to production of hydroxyl radicals necessary for the treatment process. The micro-bubbles produce by the system increases the overall efficiency and thereby reducing the retention time needed for each process. Tertiary treatment are also in place to make sure DAO 2016 parameters will be achieved consistently or in some cases recycling for non-potable use is still economically feasible.

The ELFLASH Construction Services Advance Oxidation Process System strong points includes low operation and maintenance cost, tolerable noise emission level (less than 45dB), low odor emission and modular in nature for area availability issue.

Products & Services

The Advance Oxidation Process as applied on hospitals, clinics, dialysis centers and other healthcare facilities has been on the scene since 2009. The ELFLASH Construction Services Advance Oxidation Process setup proves to be effective even in the presence of antibiotics, chemical reagents and disinfectants on the wastewater stream. Old installations designed for DAO 35 has been successfully upgraded to DAO 2016 with minimal cost. Present design is even more flexible as it is ready for upgrading to 100% recycling option.

The Advance Oxidation Process as applied on hospitals, clinics, dialysis centers and other healthcare facilities has been on the scene since 2009. The ELFLASH Construction Services Advance Oxidation Process setup proves to be effective even in the presence of antibiotics, chemical reagents and disinfectants on the wastewater stream. Old installations designed for DAO 35 has been successfully upgraded to DAO 2016 with minimal cost. Present design is even more flexible as it is ready for upgrading to 100% recycling option.

The Advance Oxidation Process in combination with effective oil interceptor and oil digester has been proven effective on food industries. The oil digester is an exclusive design of ELFLASH Construction Services, it solves the problem of FOG disposal common on food industry. The oil digester treats FOG to minimize foul odor, reduce the volume by as much as 90% and renders it degradable.

The Advance Oxidation Process as applied on hotels, resorts, condominium units and other developments residential in nature has been a perfect fit. The process which produce minimal noise level, tolerable odor emission and high quality of effluent discharge is best suited for highly populated area with strict environmental regulations.

The Advance Oxidation Process is the best option for light industry such as warehouses, logistics, offices and BPO centers that produces minimal volume of pollutants but still need compliance. The process produces minimal noise level, tolerable odor emission and high quality of effluent discharge is best suited for this industry usually located on urban areas with strict environmental regulations.

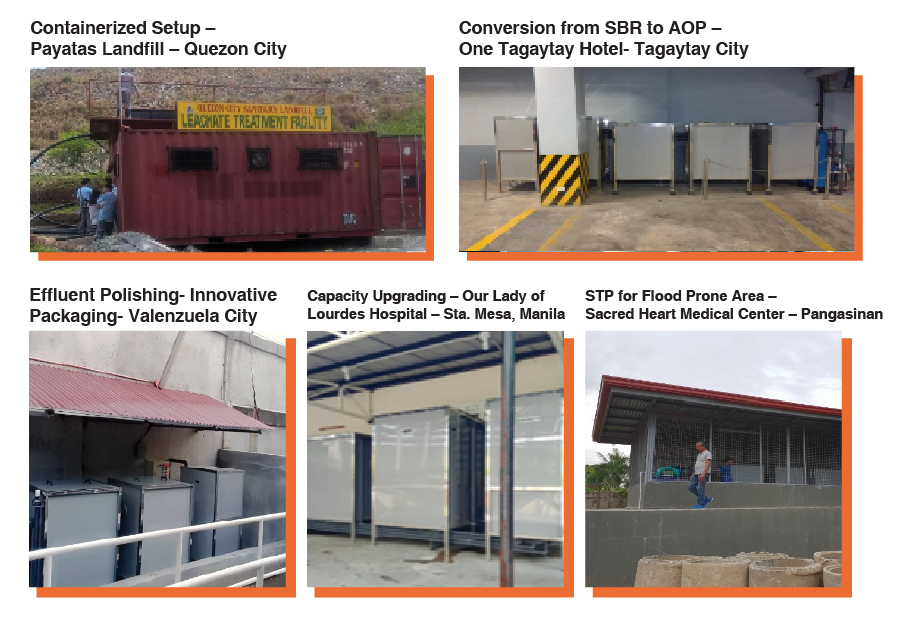

The Advance Oxidation Process is proven to be a very versatile technology when it comes to flexibility on applications. It can be use as pre-treatment, polishing setup, capacity upgrading, cost reduction measure and many other possibilities.